If you work in the fashion, lifestyle, or sportswear industry, then the term tech pack will be familiar to you. A tech pack is the key to transforming your unique ideas into a production-ready design. It streamlines communication between designers and manufacturers, prevents costly mistakes, and allows you to create a perfect product. In this guide, we’re going to cover everything you need to know about tech packs and why they are so crucial for the success of fashion and sportswear brands.

What is a Tech Pack in the Apparel Design and Sportswear Production Process?

Tech Pack Definition

A tech pack is a detailed instruction that communicates design specifications for a fashion or sportswear item. It has everything that you need to create a piece of clothing; the dimensions and any other information required for construction are all there. In the land of performance wear and athletic apparel, a tech pack also includes fabric treatments and other specs (for instance, telling the manufacturer to use moisture-wicking fabrics or breathable material). It serves as the definitive protocol for manufacturers, ensuring that the finished product aligns with the designer’s intention and meets technical requirements.

Tech Packs’ Importance for Clothing and Sportswear Brands

Tech packs are a tool used to narrow the gap between what creative teams imagine and what is actually produced. They keep every stakeholder, from those making the designs to those on the factory floors, aligned. When tech pack contents are detailed, you save time and reduce errors, making more products that satisfy your brand. For sportswear-based lines, a good tech pack will focus on those functional aspects like mobility, airflow, and durability.

Who Uses Tech Packs in the Apparel Supply Chain?

Tech packs are vital to many people in the garment industry. Here’s who typically uses them:

Fashion Designers

The designers themselves put together the initial designs and sketched out their vision in what is known as a tech pack. Includes all of the specs needed for manufacturers to make this a reality.

Sportswear Product Developers

Designers concentrate on technical aspects of sportswear and develop items that respond to performance requirements like durability, comfort, etc.

Apparel Manufacturers

Inspection manufacturers depend on tech packs to know the details of a job, from materials to production schedule. An explicit tech pack reduces the chances of miscommunication and ensures fewer hiccups in your production process.

QC & Sourcing Teams

Quality control and sourcing teams can refer to the tech pack from time to time, making sure that the materials are meeting the standards and products are sourced and manufactured as per the mentioned specifications.

Advantages of Using a Tech Pack for Fashion and Sportswear Development

Minimizes Production Errors and Miscommunication

They ensure a smooth production process and are less likely to have errors because there is minimal room for interpretation. All parties involved — designers, developers, makers alike — have a clear standard to focus on per brand vision and quality.

Reduces Lead Times and Accelerates Time to Market

With fully baked-in details, manufacturers can ramp up production more quickly, effectively bringing products to market faster. If anything, it is more important for sportswear brands to keep up with the competition and put out new styles of athletic wear that the market is looking for.

Essential for Performance Wear Specifications

For performance wear, a tech pack is more than just measurements and fabric selection. It includes the technical details like sweat-wicking technology, stretchy fabric, and breathable fabrics to ensure the result is of a high standard for those competing in such a sport.

Makes Re-orders and Product Improvements Easy (and inevitable)

When a tech pack is established, it becomes a point of reference for subsequent orders. This consistency means that reorders are seamless, and any modifications or additions to the design come across loud and clear to factories.

You Know It’s Working With Sportswear Makers as a Production Model

A tech pack is a production blueprint for manufacturers, with the process, materials, and quality all described. That means less guesswork and quicker, more efficient production runs.

Aids in Technical Apparel Quality Control

Quality control staff members employ the tech pack to compare what’s been delivered with initial specifications, verifying that technical apparel meets performance and quality standards before it hits the shelves.

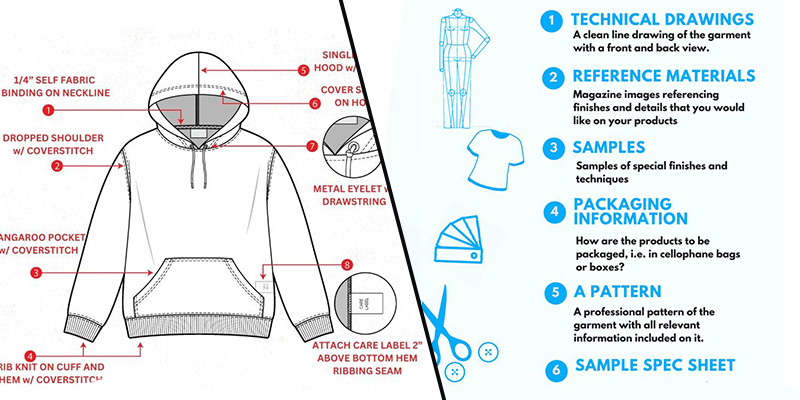

A Fashion or Sportswear Tech Pack Should Have These Elements

Product Overview or Cover Sheet

The cover sheet offers an overview of the product, including high-level details such as style name, product category (for example, sportswear tech pack), and designer. It is the opening page of tech pack where all essential details are shared.

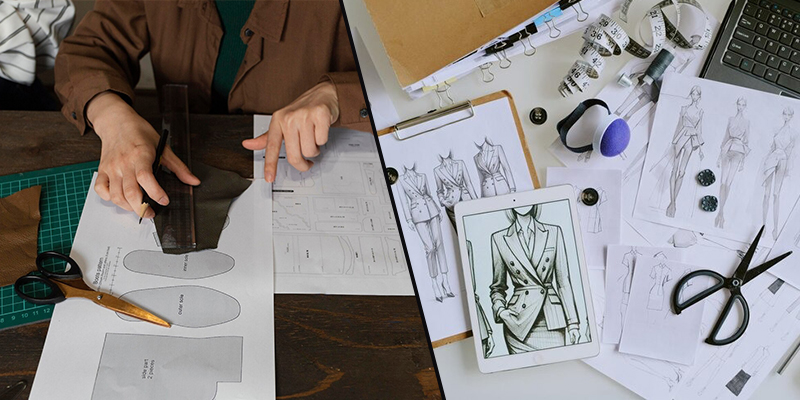

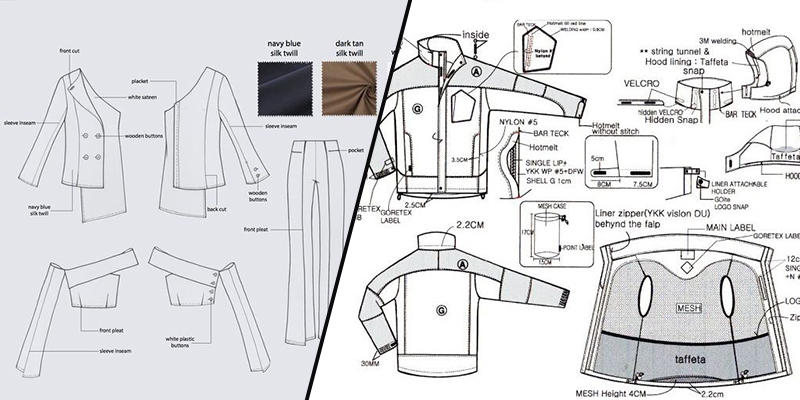

Technical Drawings/CAD Sketches (Front + Back View)

Tech Pack Must Have: CAD Sketches. These front and back views confirm the design of the style, showing details such as seam lines, pocket position, and any other design elements. This reference design can be considered as a visual aid in order to understand the design in detail.

Fabric, Trims, and Material Details

This portion describes the fabrics and trims used in sportswear. Information on moisture-wicking fabrics, stretch material, and reflective trims has been added to make sure the clothing you are wearing is going to work just as hard as you.

Dry or Stretch Fabric Features(for Sports Wear)

Moisture-wicking and stretch performance fabrics are crucial in athletic wear. And that even the fabrics’ type, weight, and sources are all specified in a “tech pack” to ensure they hold up and wear comfortably.

Colorways and Artwork Placement

This page gives colour specifications for various parts of a garment and explains where to position logos, labels, or artwork on the clothing. It adds uniformity to pieces.

Size Specifications and Grading Rules

Grading size specifications and grading rules are part of the techpack to guarantee fitting correctness for all sizes. These specifications need to be in place for production runs and prototypes.

Construction Details and Stitching Guidelines

This part describes the stitch, for example, flatlock stitching used for active wear. It’s the practical way to make sure it has longevity and is comfortable, especially for performance!

Bill of Materials (BOM)

The BOM contains a listing of all resources (fabrics, trims, and hardware). It’s an excellent part cost estimator with several different machines for manufacturing.

Labeling, Tags, and Packaging Requirements

All products consist of branding through labels and tags. The tech pack will detail where and how to keep the consistency across all products.

How to Create a Tech Pack for Fashion or Sportswear: The Process, Step by Step

Step 1: Define What the Product Should Do and Why

Before setting out to create a tech pack, understand what the product requirements are, what it is, who it is for, and how is / it will be used. For performance sports wear, this understanding will be the needs of a specific sector of the industry.

Step 2: Flat Sketches or CADs Time!

Create elaborate flat sketches or CADs showing how your garment will look, its details, and construction methods.

Step 3: Design: Fabric and Trim spacing (Performance Requirements included)

Description of all the fabric and trim required, also whether this includes fabrics that are moisture-wicking or fabrics with stretch for sportswear.

Step 4: Include sewing details and construction Instructions

Give specific directions for sewing and construction that will make the garment as tough as it needs to be.

Step 5: Start Adding Size Specs and Grading Charts now!

Also include size charts and grading rules to allow any size to fit the product.

Step 6: Full BOM and Costing Sheet.

You really need to go through each part on your Prototype Board assembly and figure out how much it costs in quantity one.

Make a BOM to keep every component organized and have the costing sheet for real, pure transparency!

Step 7: Work With, Edit, and Share With Manufacturers

After the tech pack is finished, work with manufacturers to get everything done and communicated for any changes.

What is the difference between the tech pack of sportswear and fashion wear?

| Category | Sportswear | Fashion |

| Fabric Specification | Specifies GSM, 4-way/2-way stretch %, moisture management (e.g., ASTM D4966, AATCC 195) | Notes basic fabric type, weight, and color; rarely includes lab test data |

| Performance Testing | Requires mechanical testing (e.g., tensile strength, abrasion resistance, recovery rate) | Testing is often skipped unless for high-end garments or strict compliance markets |

| Stitching & Seam Details | Specifies seam type (e.g., flatlock, overlock, coverstitch) for performance and durability | Generally lists standard seams (e.g., single needle, overlock) without performance goals |

| Pattern Engineering | Includes articulated paneling, gussets, and motion-mapped zones based on body kinetics | Straightforward pattern blocks with emphasis on silhouette, not function |

| Tolerances & Fit Specs | Tight tolerances due to stretch fabrics and high movement use (e.g., ±0.5 cm max) | More relaxed tolerances, vary by brand and target market (e.g., ±1–2 cm) |

| Bill of Materials (BOM) | Includes technical trims (e.g., coil zippers, stretch mesh, elastics with recovery specs) | Decorative trims are common (e.g., metal buttons, lace), and there are fewer functional performance notes |

| CADs / Line Drawings | Often includes movement zones, ventilation mapping, and bonded seam placements | Basic front/back CADs with focus on style lines, prints, and finishes |

| Grading Rules | Body-scan-based or activity-specific grading (e.g., for cyclists, runners, gym users) | Standardized size grading (S–XL or 2–14) based on fashion fit blocks |

| Packaging & Folding | May include folding instructions to protect performance finishes or compression garments | Standard folding/packing unless luxury or delicate fabric is used |

| Labeling Requirements | Must include fiber content + compliance labels (e.g., REACH, OEKO-TEX®, UPF rating) | Basic care labels; compliance only where required (e.g., for exports) |

Avoid These Common Tech Pack Mistakes in Performance Wear

If you’re working on activewear or any kind of performance gear, your tech pack has to do more than just “check the boxes.” Unlike fashion basics, these garments need to perform—which means the details matter. A lot.

Here are some common mistakes people make when putting together tech packs for performance apparel—and how to avoid them:

1. Using a Generic Template

Performance gear isn’t basic fashion. Using a one-size-fits-all tech pack template just doesn’t cut it here. Activewear needs more technical details—stretch, durability, breathability, etc. Generic templates usually leave these out.

What to do instead: Customize your tech pack to match the garment’s purpose. Think about movement, sweat, impact—whatever the product is designed for, and reflect that in your specs.

2. Leaving Out Fabric Performance Info

Saying “polyester/spandex” isn’t enough. Is it moisture-wicking? UV-protective? How does it handle sweat? These are key questions when you’re working with performance fabrics.

Fix it by: Including specific fabric performance details. If it’s sweat-wicking, say that. If it has a special coating or is OEKO-TEX certified, call that out. Don’t make your factory guess.

3. Skipping Grading and Tolerances

Fit is everything in performance gear. It can’t be too loose or too tight, and it needs to fit consistently across all sizes. Without clear grading rules or tolerances, you’re asking for fit issues.

How to fix it: Always include a properly graded spec sheet. Add tolerances too (e.g., +/– 0.5cm) so the factory knows how much wiggle room they have.

4. Not Including Visuals or Branding Assets

You might think the design is clear, but without visuals, the factory is left to guess. That leads to mistakes.

What to include: Clear CADs, logo placements, colorways, trims, and any branding guidelines. The more visual, the better—factories need to see what you’re imagining.

5. Forgetting Proper Care Instructions

Performance fabrics can be sensitive. If the care label is wrong or missing info, customers could ruin the product on the first wash—and blame your brand.

Avoid this by: Including proper care instructions based on the fabric blend and finish. Be specific. If it needs a cold wash and hang dry, say so. And double-check the care symbols. References like CAD sketches to comprehend design aspects. Ensure that these are part of the tech pack.

Ever Blanking on How to Care for Techy Fabrics

Care labels guide the lifetime of sportswear and technical fabrics. Flaws in these can result in dissatisfied customers.